Drain-to-waste systems, conventional drip irrigation systems, and some other hydroponic techniques can be readily converted to Blumat Watering Systems with great success.

However, there is a learning curve while making the switch over! The concepts behind Blumat Watering Systems are very foreign to hydroponic (and often coco/perlite) cultivators, and they often end up frustrated with Blumat systems. In reality, they’re a few minor adjustments away from throwing their feet up and watching their plants thrive!

Differences in Concept

No Run-Off

In traditional drip systems and drain-to-waste facilities, plants/containers are often watered to the point of run-off. When water and/or nutrient solution runs off, it causes several problems: over-watering/less-than-optimal growth speed, water waste, nutrient waste, and environmental degradation (e.g. algae blooms, pollution, salt build-up, etc.).

In a properly-functioning Blumat Watering System, there’s never run-off. This directly translates to lower water as well as nutrient costs. Not only are nutrients no longer being wastefully dumped into a drain (or worse–the ground!), but overall nutrient concentrations can be lowered. Because all of the nutrient solution makes it to the root zone in a Blumat system, the concentrations can be lowered to 50-25% dilution rates of a drain-to-waste system. If nutrients are used at manufacturer’s recommended rates in a Blumat system, excessive build-up is probable, which can lead to nutrient lock-out, burning, and stunting. Less is more in a Blumat System!

Indirectly, avoiding run-off (and over/under-watering) means optimal growth and maximization of biomass production. It also indirectly reduces the burden on dehumidifiers, air conditioning, and other temperature/humidity control infrastructure, ultimately resulting in lower power use/cost without sacrificing any yields.

Results in lower nutrient use, lower water, lower humidity, lower power use, lower AC/appliance demand, etc.

Static Moisture vs. Wet/Dry Cycling

Coco/perlite and hydroponic growers have long-championed the concept of wet/dry cycling. The general idea is that by alternating between a relatively wet/relatively dry growing media, it encourages the plants to grow roots out to the entire container. Sounds pretty good, right?

The reality is that there is a Goldi-Locks zone of moisture content (it does change from media to media, and does depend on environmental factors like temperature, ambient humidity, etc.) that any given plant species or cultivar thrives in. The plant wants a relatively stable environment, with minor swings in temperature, humidity, moisture, etc. Any cultivator who rapidly swings their RH, temperature, or other environmental factors will attest to the stressful effect it has on plants!

When plants are cycled from wet to dry and back again, they go through times when they are over-watered, under-watered, and everything in between. This results in less-than-optimal growing speeds. When plants are watered to the optimal level at all times (aka the “Goldi-Locks zone”), they won’t waste any time being stunted–all available resources in the plant are oriented toward growth!

Constant Water Supply vs. Use of Timers & Valves

Blumat Watering Systems require a constant supply of water–this is usually the hardest concept for cultivators to understand!

Blumat sensors are self-regulating, and need a water supply to maintain their regulatory function. When a Blumat sensor does not have a water supply and surrounding soil dries out, it pulls the valve in the Blumat completely open. When water supply is restored, it ends up flooding containers, or even worse–the whole garden!

Traditional drip systems and drain-to-waste systems are generally regulated by timers and valves–water is only supplied to drip emitters on a schedule.

If a Blumat System is over-watering or under-watering the Blumat sensor valves simply need to be adjusted. The water supply should not be turned off!

Growers conditioned to conventional drip systems are of the mind that if the plants need water, the system needs to be turned on–if they don’t need water, the system should be turned off. Blumat Watering Systems can be adjusted simply by adjusting each individual sensor–the system is “on” alert every moment of every day.

Practicalities & Methods

Traditional drip systems can be easily converted into Blumat Systems. The system pictured above was converted in a matter of minutes!

Typically, drip systems use transfer barbs to get from a water supply line (1/2″ poly tubing in the picture above) to drip emitters. Generally, the transferring tubing is 1/4″ diameter.

In this case, the cultivator removed the conventional drip emitters, which left an open 1/4″ end of tubing. A simple 1/4″ x 3mm adapter was inserted, and the 3mm tubing in each Blumat readily attached to this adapter.

A pressure reducer should be placed at the water source so as not to put excessive pressure into the Blumat system.

Once the reducer is installed and each Blumat has been calibrated, the cultivator’s irrigating work is essentially done.

The concept behind retrofitting any system to a Blumat system is to get a water supply to each Blumat sensor–using either 8mm or 3mm tubing.

For Containers Requiring More than a Single Point of Emission

We recommend using distribution drippers to extend the watering ability of each blumat sensor. For example, if your pre-existing drip system has plants in 15-gallon containers or so, you may want water being distributed more evenly throughout the container, as opposed to being emitted into a single point in the container.

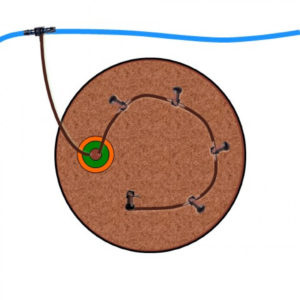

Here is an example configuration:

In this configuration, a Blumat sensor leads into distribution drippers (using 3mm tubing), which help evenly spread moisture throughout the container.

Incoming Pressure

Most conventional drip systems use relatively high pressures to operate. Blumat systems must be under 15PSI to operate–anything more will actually push the connections apart.

A Blumat pressure reducer should be installed prior to the actual Blumat emitters:

This reducer is designed for in-line installation in 1/2″ or 3/4″ polyvinyl tubing–the standard for most conventional drip irrigation systems!

General Advice

- It is recommended to dilute nutrient solutions by at least 50%, and up to 25% when converting drain-to-waste systems to Blumat systems (since there’s no run-off in a Blumat system, the solution should be diluted to avoid nutrient build-up)

- Biofilm Buster is recommended for those putting organic nutrients through a Blumat system, and Dripclean is recommended for cultivators using salt-based nutrients in a Blumat system

- If you’re accustomed to the idea that “system on=water the plants, system off= don’t water the plants”, you’ll need to change your thinking! Blumat systems self-regulate, and if the volumes of water they’re delivering are inappropriate, they simply need to be adjusted–NOT turned off!

- Never run water supply to Blumat systems over 15PSI!

Related Parts

- 1/4″ x 3mm Barb

- 1/4″ x 3mm Transfer Barb

- 1/4″ x 8mm Barb w/ Valve

- 5″ Tropf Blumat

- 9″ Tropf Blumat

- 3mm Tubing

- 8mm Tubing

- Biofilm Buster

- Dripclean

- Distribution Dripper (In-line)

- Distribution Dripper (Concluding)

- Blumat Pressure Reducer

- Blumat Pressure Reducer w/ Perma-Loc Fittings