Overview

Blumat Watering Systems are composed of modular components that can be configured in a plethora of ways to accomplish as many goals.

This adaptability allows for creative designs, as there are many different ways to achieve a goal using Blumat Watering Systems. However, there are some design principles that should be followed for best practices.

Blumat Watering Systems are composed of two distinct components: a water supply system, and plant kit/container systems.

Once an adequate supply system is designed/implemented, plant container kits can be integrated for operation.

Following these guidelines will help minimize labor, maintenance, and other problems while maximizing consistency, ease of user-experience, and overall performance of Blumat Watering Systems.

Water Supply

Blumat Watering Systems require a constant supply of water, as they are self-regulating devices, and require a water supply to self-regulate. Cutting Blumat components off from water for extended periods of time, fluctuating incoming pressure, or air/gas in the supply line will all reliably cause problems for the operation of the system.

There are three general options for supplying a Blumat System with water.

Water Sources

Blumat Systems can be supplied via one of three ways:

- Gravity-Fed (via elevated reservoir/pond/etc.)

- Pressure-Fed (pre-existing well pump, municipal line, etc).

- Pump-Fed (Using a pump/accumulator tank/pressure reducer such as a Pump Kit)

Depending on whether the system is fed via gravity or by pump/pressure, we recommend configuring water supply lines differently. A loop is recommended for a gravity feed, while straight rows can be used in pump/pressurized systems.

Gravity-feeds are generally ideal for smaller systems and systems utilizing Blumat senors and distribution drippers (as opposed to BluSoak drip tape).

Pressurized feeds are recommended for larger-scale systems, and those utilizing Blusoak drip tape.

Supply Placement: Ceiling vs. Ground-Level

Water supply tubing can be placed on the ground level for easy maintenance and budget-friendly configurations. This is ideal for gardens/facilities with small numbers of gardeners, outdoor gardens, and gardens with containers/beds that will not be moved.

For larger gardens, those with many employees, indoor facilities, and facilities that need to move containers/beds (even if just a few feet side to side for maintenance), it is recommended to run main water supply along the ceiling. PVC tubing is favored for this, as it is stiff and will not sag like polyvinyl drip tubing.

The tubing can come down from the ceiling to each table, raised bed, bench, or garden area and adapt into smaller water supply line (such as 8mm tubing). This type of configuration eliminates water supply tubing on the floor or ground, and therefore minimizes the likelihood of someone tripping or otherwise running into a conflict with the irrigation system.

Loops vs. Lines

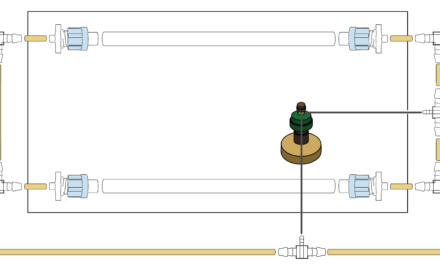

Water supply can either be configured in a “loop” that encompasses plant rows, or in “lines”–one line per plant row (or one line for every other row in a budget configuration).

Loops are recommended in gravity-fed systems, as the increased number of connections in the water supply tubing will assist in equalizing pressure and minimizing pressure gradients/differentials in the water supply tubing.

In pressurized systems, this is not a problem–the relatively high pressure in the tubing will self-regulate better than in a gravity-fed system, and loops are not necessary. Straight lines down each row of plants can be configured in a pressurized feed.

Flush/Purge Valves

Flush or purge valves are recommended in all Sustainable Village irrigation systems. The installation is extremely simple, and the placement of each valve is determined by the water supply design configuration.

In pressurized systems, the valves can simply be used to conclude lengths of tubing (in place of an “end plug”).

If the cultivator suspects air, debris, or anything else undesirable in the tubing, the valve is opened to allow for free flow out of the system. The pressure in the system should push any problematic matter out the end of the tubing. The valve can then be closed, and normal operation should resume.

In a gravity-fed system (generally designed with loops of water supply), the purge valve should be placed in the loop at the point furthest from the input points from the reservoir. This will maximize the pressure gradient in the water supply tubing, and any undesirable material will be pushed out of the system at this point in the same manner as in a pressurized system.

Kits/Containers

All of the container kits on the Sustainable Village website can be readily integrated to 8mm water supply tubing.

The kits are pre-designed for containers based on the volume of each container, or square footage.

Irrigating Plants vs. Media

Whenever designing Blumat or EasySoak systems, it is useful to think about irrigating soil or growing media rather than irrigating individual plants.

The reason for this is that Blumat carrots sense moisture levels in the soil or media. In a raised bed or larger container for example, a uniform moisture level should be maintained for optimal growth. Wet/dry pockets in media will prune roots and otherwise discourage optimal plant growth.

When irrigation systems are designed to water plant sites (for example in the ground or in raised beds), they’ll only encourage root growth around the irrigated area. If an entire raised bed is adequately irrigated, it does not matter if the bed has 100 small plants, or 1 giant plant–the soil is irrigated to optimum moisture levels, and therefore the plant roots can occupy the entirety of the container, utilizing nutrients, water, and valuable canopy space to the maximum.

Additional Options/Accessories

There are additional “bells & whistles” that can be added to any Blumat Watering System. In general, the bells/whistles have the potential to increase performance, convenience, or both aspects of a system.

Quick-connect fittings can be added to seamlessly integrate/disintegrate plants/containers from the system.

The same fittings (available in different sizes), can be used to quickly and easily connect/disconnect water lines, beds, tables, benches, plant rows, or switch from one water supply source to another (i.e. from a hose bibb to a rain barrel).

There are quick-connect fittings that use a valve, as well as those that automatically stop/start flow when they’re disconnected and connected, respectively.

Digital or analog moisture meters can be used to inform and assist in Blumat System calibration. The digital displays are generally recommended, as the analog meters are significantly more expensive. These components ease the learning curve and assist in dialing the Blumat system in.